Corrugated boxes are a popular choice for packaging, shipping, and storing a variety of products. Constructed from corrugated paperboard, these boxes feature three layers: an inner liner, an outer liner, and a wavy, fluted medium layer. The fluted layer adds both strength and cushioning, making these boxes ideal for protecting items during transit and storage.

One of the key benefits of corrugated boxes is their versatility. Their robust construction allows them to handle a diverse range of products, from delicate items to heavy goods. Additionally, they are cost-effective, offering a good balance between performance and affordability.

Whether you are shipping items nationwide or storing inventory in a warehouse, corrugated boxes offer reliable protection and peace of mind. Their strength, adaptability, and economical nature make them a crucial packaging solution for businesses of all sizes.

Corrugated Board is comprised of three fiberboard layers; two linerboards sandwich a middle sheet that is in a wave-shaped a pattern of arches known as flutes. These flutes are anchored to the linerboard with an adhesive.

On end, flutes form rigid columns, capable of supporting a great deal of weight. From the side of the board, the space between the flutes acts as a cushion to protect the container’s contents. Flutes also serve as an insulator, providing protection from sudden temperature changes. The linerboard provides additional strength and protects the flutes from damage.

The thickest and most robust, ideal for heavy or fragile items.

Medium thickness, offering a balance between strength and printability, often used for food and retail packaging.

The most common type, providing a good mix of strength, cushioning, and printability, suitable for general shipping and display boxes.

Thin and lightweight, perfect for small boxes and point-of-purchase displays.

Accupak’s manufacturing setup seamlessly combines advanced management, modern machinery, and quality control.

Capacity, a goal-driven culture, premium packaging capabilities, facility pride, the list goes on. For Accupak, continuous improvement has become a way of life.

Slotted boxes vary in design: some feature equal-length flaps for efficiency, others lack one set of flaps for simplicity. Overlapping flaps offer added durability and cushioning, while die-cut panels enable quick assembly, ideal for small shipments

In this design, all flaps have the same length. The two outer flaps (typically on the longer sides) are half the container's width, so they meet in the middle when folded. A padding insert can be placed between the bottom inner flaps for extra protection. This style is very efficient, with minimal material waste, and is the most widely used box type.

Similar to a Regular Slotted Container (RSC) but missing one set of closing flaps.

The flaps are as long as the box's width, nearly overlapping each other. This design is highly durable against rough handling, adds extra cushioning when laid flat and stacked, and enhances stacking strength.

The bottom is formed by four intersecting die-cut panels, making it quick and easy to assemble. Ideal for small-volume shipping, but may not support heavy items due to the bottom not being fully secured.

This box is cut into a square cross shape, allowing all four sides to fold up and over. It is ideal for shipping delicate items like artwork or books.

This box is cut into a square cross shape, allowing all four sides to fold up and over. It is ideal for shipping delicate items like artwork or books.

This type is cut from a long piece of board with multiple folds, each featuring a side panel. It is commonly used by automated machinery to wrap a product snugly. When assembled, the box has an uninterrupted top and bottom with only the sides flapped. Unlike the standard RSC (Regular Slotted Container) box style, this can be custom-sized to fit the product precisely.

This type is cut from a long piece of board with multiple folds, each featuring a side panel. It is commonly used by automated machinery to wrap a product snugly. When assembled, the box has an uninterrupted top and bottom with only the sides flapped. Unlike the standard RSC (Regular Slotted Container) box style, this can be custom-sized to fit the product precisely.

This box is made from a long, scored board with an additional fifth panel for tucking in. Once assembled, each side of the box has double layers of board for extra protection, making it ideal for stacking or shipping items that could puncture the sides. It's great for long or heavy flat objects like golf clubs, fishing rods, or hacksaws.

This box is made from a long, scored board with an additional fifth panel for tucking in. Once assembled, each side of the box has double layers of board for extra protection, making it ideal for stacking or shipping items that could puncture the sides. It's great for long or heavy flat objects like golf clubs, fishing rods, or hacksaws.

This box is a one-piece, rectangular, elongated, and scored design that creates strong sides with a lid that securely tucks in. It’s commonly used for bakery products, medical supplies, and shoes.

This box is made from a single elongated board with three foldable pieces and attached side pieces, forming a sturdy tray with walls but no cover. It's typically used for sales displays or where products are sold 'by the case.'

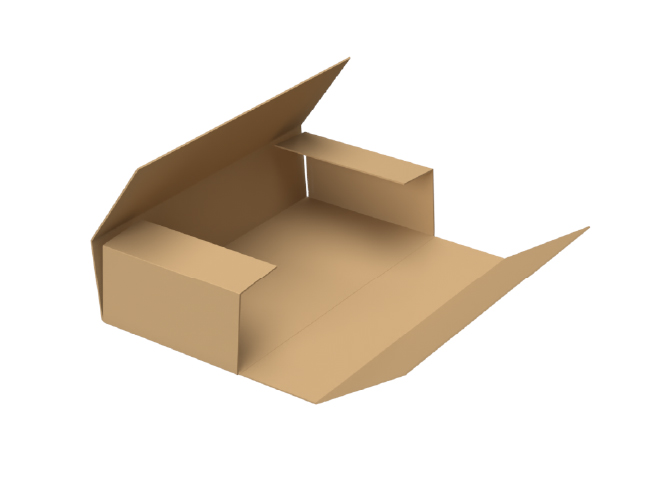

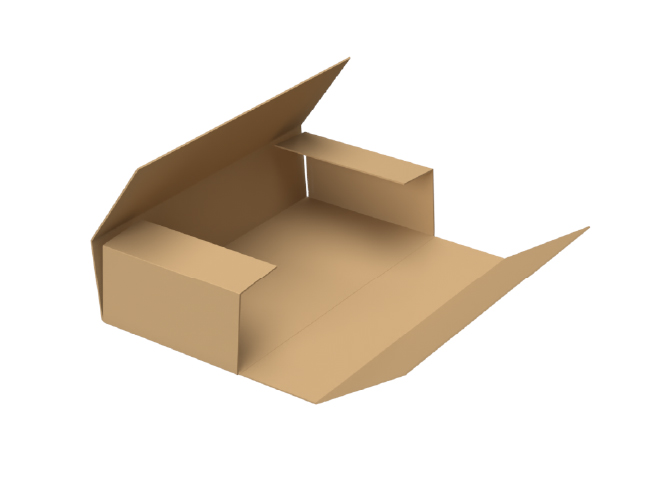

Self-Erecting Containers These boxes are stored flat, with certain panels already glued for quick and simple assembly.

The bottom of the box is pre-glued, while the top flaps are like those of a regular slotted container. For a telescopic design, two self-erecting boxes can be combined to form the top and bottom.

Telescope Boxes These boxes come in at least two sections: a base and a lid. One piece slides over the other to close.

In truck and rail systems, a box is categorized as Telescope style if the lid extends over two-thirds of the box’s depth. If the lid extends less than two-thirds, it is considered a box with a cover. The durable lid, especially with extended sides, adds extra strength.

An open box paired with a matching lid, designed for easy or frequent opening and closing, such as for shoeboxes, cosmetics, jewelry, or household items.

The body of the box is a tube, with removable top and bottom lids. This style is ideal for products that are too heavy to be placed inside a standard box, like refrigerators.

Printed Corrugated boxes are available in various styles, each offering unique finishes and features. From cost-effective options with durable prints to high-quality designs with sharp and vibrant colors, there are solutions for every packaging need. Additional enhancements like lamination and UV coating provide extra protection and a polished look, ideal for premium packaging. For eco-conscious choices, sustainable materials are also combined with high-quality printing for an appealing and environmentally friendly option.

Printed Corrugated boxes are available in various styles, each offering unique finishes and features. From cost-effective options with durable prints to high-quality designs with sharp and vibrant colors, there are solutions for every packaging need. Additional enhancements like lamination and UV coating provide extra protection and a polished look, ideal for premium packaging. For eco-conscious choices, sustainable materials are also combined with high-quality printing for an appealing and environmentally friendly option.

Corrugated boxes offer superior strength and cushioning, making them ideal for protecting a wide range of products during shipping and storage. Their versatility and cost-effectiveness make them a preferred choice for businesses seeking reliable packaging solutions.

The corrugated design of the flute functions like miniature beams, greatly enhancing the box’s ability to withstand compression. This feature allows fluted boxes to carry heavier loads without collapsing.

The flutes create air pockets that act as cushioning layers, effectively absorbing impacts and providing strong protection for fragile items. This ensures that contents remain secure and undamaged during shipping, even when subjected to rough handling.

Due to the strength provided by the flutes, these boxes retain their shape and structural stability, making them ideal for stacking. This stacking feature maximizes storage efficiency and prevents boxes from collapsing under the weight of others.

The smooth liners of fluted boxes offer a perfect surface for printing designs, branding, or important information directly on the box. This allows for enhanced brand visibility and customization to suit specific marketing or labeling needs.